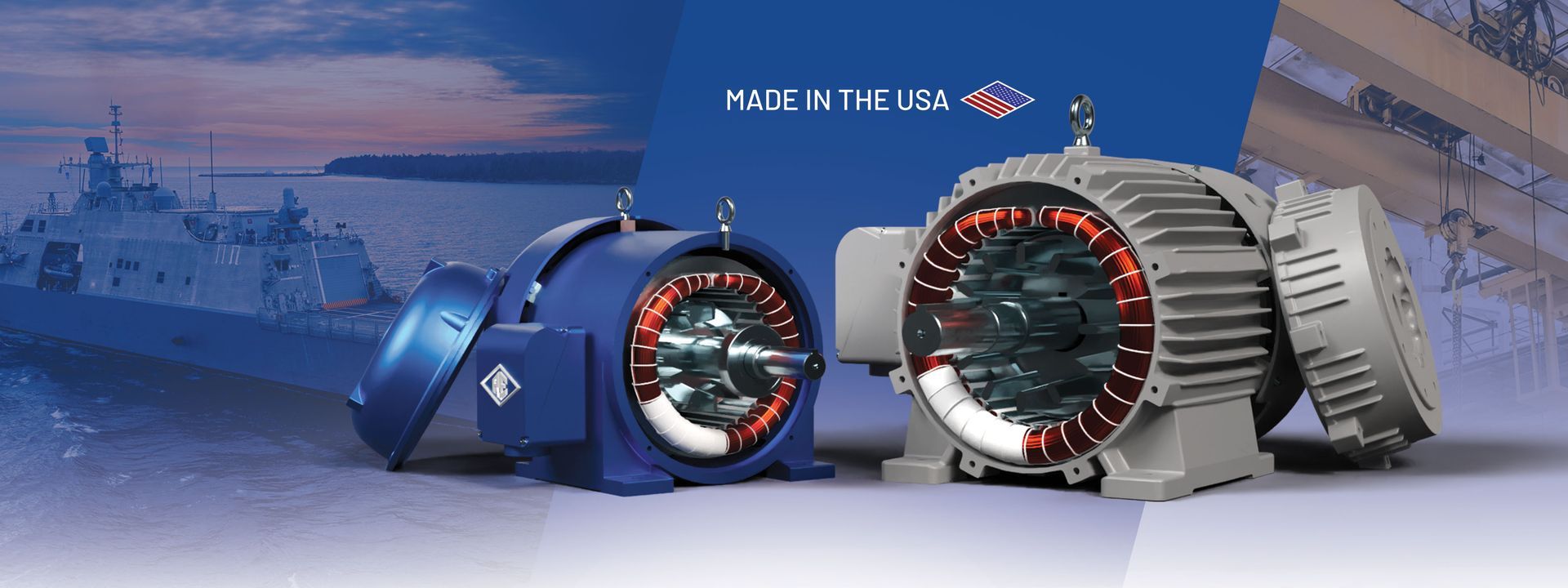

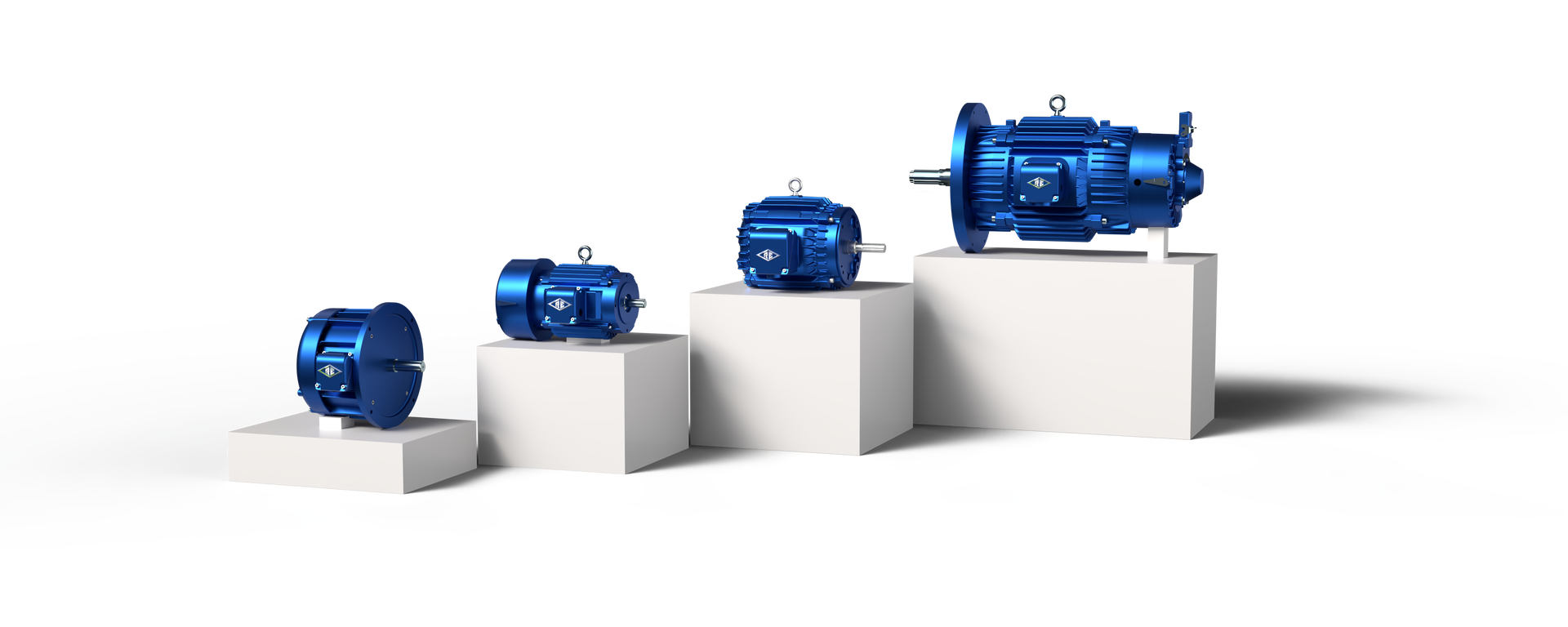

Our customers rely on high-performance electric motors and motion control solutions that operate in the most demanding industrial applications. To meet those expectations we’ve made significant investments across our U.S.-based motor manufacturing facilities.

With expanded operations in

California and Michigan, we’ve strengthened our vertically integrated manufacturing network, increased production speed, and enhanced quality control at every stage of the electric motor lifecycle. The result: shorter lead times, higher consistency, and greater flexibility for custom electric motor applications.

Vertically Integrated, Designed Around You

By expanding and modernizing four key production facilities, we now control nearly every step of the electric motor manufacturing process from

aluminum castings and

CNC machining to

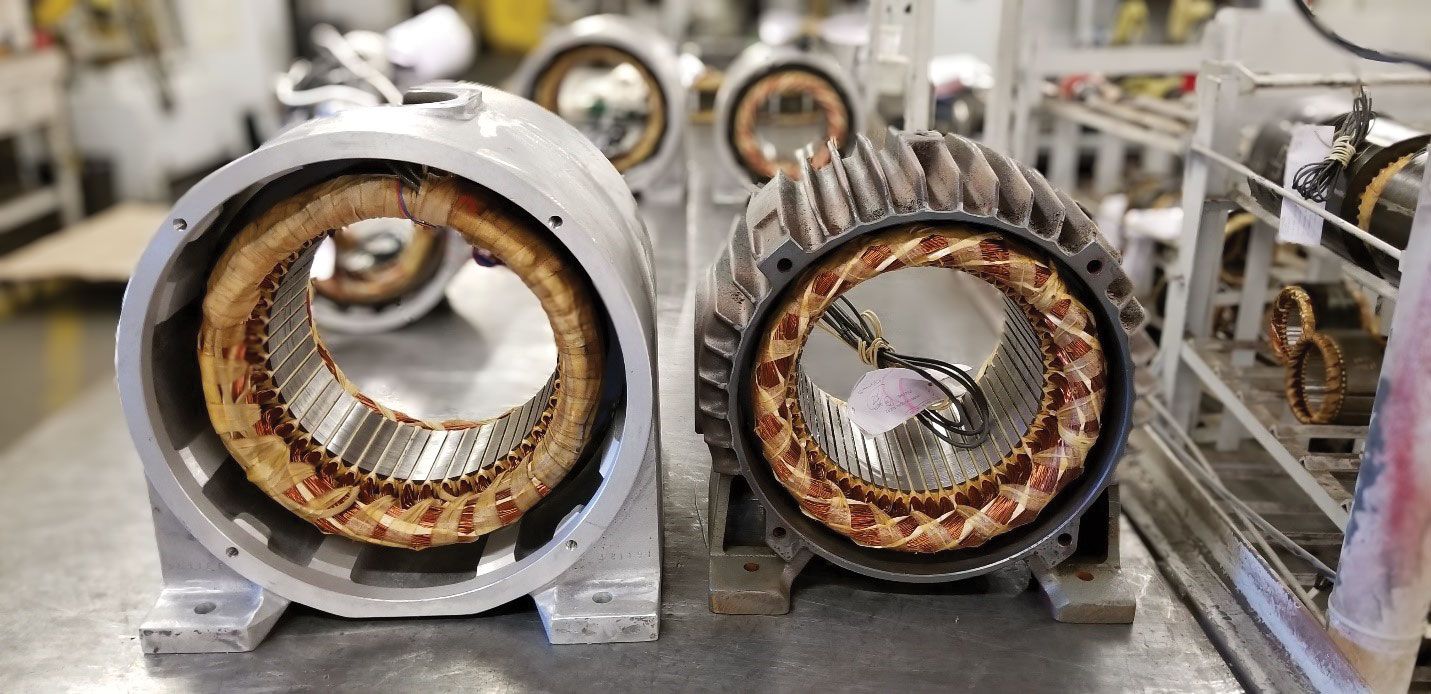

stator winding, motor assembly, and performance testing and service. This approach allows us to respond faster, maintain tighter tolerances, and deliver custom electric motors built to your exact specifications.

What this means for you:

- Electric motor lead times reduced to

4–6 weeks

- Greater quality control and repeatability across motor builds

- Faster engineering changes and

custom motor builds

- Electric motors proudly

built in the USA

Innovation Lives in La Verne, California

Headquarters, Motor Manufacturing, and Applications Engineering

La Verne is our U.S. headquarters and the cornerstone of our electric motor manufacturing and applications engineering operations. This facility specializes in advanced motor winding technology, precision motor assembly, and engineering-driven production, supported by a fully upgraded electric motor test laboratory.

Recent investments include:

- A new layout optimized for

motor winding and assembly efficiency

- Conveyor systems that improve manufacturing flow and reduce handling time

- A new Spray Tech paint booth and curing oven for consistent motor finishes

- A new test lab with a

regenerative dynamometer for electric motor testing

- Expanded

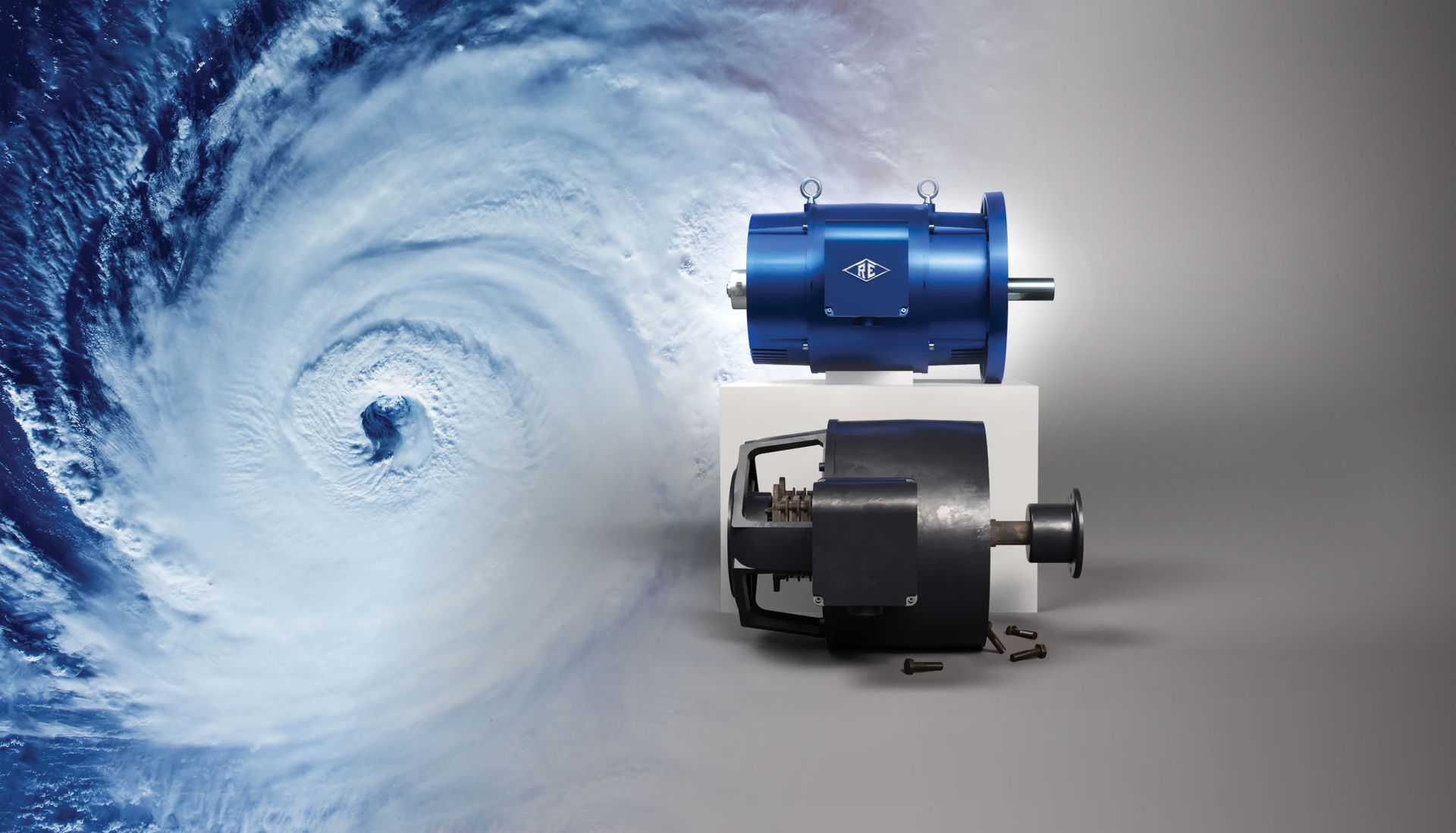

electric motor service and repair capabilities in California

These investments position La Verne to support next-generation electric motor technologies while ensuring every motor meets or exceeds performance expectations before delivery.

Precision Aluminum Castings in City of Industry, California

Strong Foundations for Reliable Motors

Our City of Industry facility operates a complete aluminum green sand foundry dedicated to producing electric motor frames, end bells, and structural motor components. With in-house pattern design, prototyping, and aluminum casting, we ensure durability, consistency, and faster turnaround for motor production.

Key upgrades include:

- A high-capacity sand silo with a precision metered feed system supplying up to

20,000 lbs of green sand per hour

- A new

120-lb bottom-pour aluminum system for faster, cleaner, and safer casting

These improvements enhance electric motor casting quality while reducing production bottlenecks, keeping your motor builds on schedule. Visit our

Reuland Castings website to learn more about our Aluminum Castings services.

Visit Reuland Castings Website

CNC Machining Excellence in Brea, California

Speed, Accuracy, and On-Demand Production

Our Brea facility specializes in CNC machining for electric motor components, including shafts, frames, end bells, terminal boxes, and more. With

14 CNC machining centers and full machine shop capabilities, we produce motor components on demand, eliminating delays caused by outside suppliers.

Recent improvements include:

- Additional CNC machining centers with planned

5-axis machining expansion

- Improved tolerance capabilities that eliminate secondary grinding operations

- New programming and process enhancements delivering up to

50% faster cycle times

- Expanded staffing and second-shift capacity to increase motor production throughput

For customers, this means faster electric motor builds, tighter tolerances, and greater flexibility when specifications or schedules change.

MANUFACTURING & ENGINEERING STRENGTH IN Howell, Michigan

Motor / Brake Manufacturing and R&D

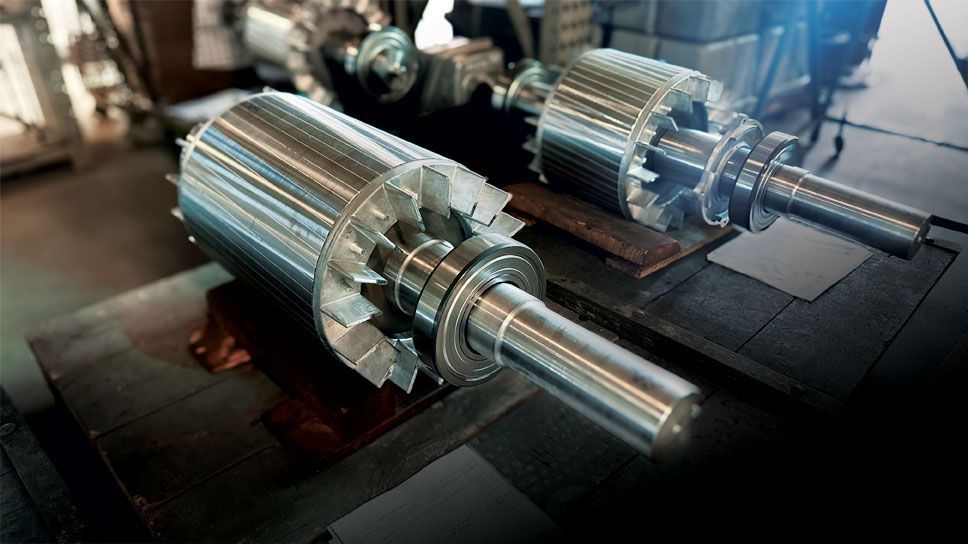

Howell is the center of our most advanced electric motor, brake, and motion control capabilities. This facility produces motor laminations, stator cores, rotors, complete electric motors,

magnetic brakes, and

fluid couplings, while also serving as headquarters for product engineering and motor R&D.

Recent investments include:

- A new

electric motor test lab with a 500 HP dynamometer

- Expanded motor winding, assembly, and service operations

- New CNC machining and

lamination stamping equipment

- A dedicated

electric motor R&D and prototype development center

- Continued growth of our engineering team to accelerate innovation

Together, these upgrades allow us to scale electric motor production while pushing performance boundaries, ensuring your equipment remains competitive for years to come.

READY FOR WHAT'S NEXT

Our expanded facilities go beyond added capacity. They create a faster, more integrated manufacturing network designed around your needs. With advanced capabilities across California and Michigan, we deliver shorter lead times, tighter quality control, and the flexibility to adapt as your requirements evolve.

From concept to final test, every investment we’ve made strengthens our ability to build reliable, American-made motor solutions. So when your next challenge arrives, we’re ready to build what’s next.